Stretch blow molding grade PET is available in solid, green and yellowish PET. The colored polymer in the reactor does not require recombination that adversely affects physical properties and improves color uniformity. A variety of pure resins with different intrinsic viscosities are available. PET copolymers crystallize slowly, which allows the production of high-quality soda beverage bottles over a wide range of processing conditions. An extrusion blow moldable polymer is also available. This material combines the advantages of good melt strength and slow crystallization rate, and can be easily processed on suitable extrusion blow molding equipment. Various reinforcing, flame retardant and other specialty polymers are continually being introduced or improved to meet new applications.

PETG copolyester is another example of many copolyesters. Unlike PCTA, which is modified with acid, PETG is a diol-modified polymer formed by combining CHDM diol with TPA (terephthalic acid) and ethylene glycol. PETG copolymers can be molded or extruded and generally retain amorphous, transparent and virtually colorless properties, even in very large cross-sections.

It has high stiffness, hardness, and good toughness, even at low temperatures. The combination of clarity, toughness and melt strength allows it to be used in injection, blow and extruded profiles, tubes, films and sheets. PETG is available unmodified or with various additives, including mold release agents, color masterbatches and impact modifiers for injection molding.

PETG should be dried at 120-160F for about 4-6 hours before molding or extrusion. The melt temperature ranged from 420F to 510F in both processes. Processing equipment should be held at higher temperatures for as little time as possible to prevent excessive degradation. Injection molding should be carried out on an injection machine, requiring 50% to 80% of its capacity per injection.

PETG can be extruded and blown at the melt temperature between 400-450F to make transparent bottles for shampoo, liquid detergent, sanitary products, mineral oil and food packaging. This material is FDA compliant for food contact.

Extrusion can produce a wide range of profiles, as well as tubing, film and sheet for packaging, including medical device packaging. PETG and PCTA can be sterilized with ethylene oxide and gamma rays.

When used for injection molding, PETG is usually processed in the melt temperature range of 450-510F, and the mold temperature is about 70-130F. Current applications include instrument covers, machine guards, cosmetic containers, lever device pointers, display components and toys.

PET is mainly used in soda soft drink packaging. PET has nearly 100% of the 2-liter packaging non-recyclable container market, and 1.5-liter, 1-liter, 0.5-liter and even smaller PET bottles have also been widely recognized.

PET is used in food, alcohol and detergents. Demand for PET in uncarbonated beverages and industrial product packaging is expected to continue to grow. Packaged foods include mustard, gum products, peanut butter, condiments, cooking oils, cocktails and fruit juice concentrates. New colors, especially Weber color PET in pharmaceuticals. Great popularity on the packaging of vitamins and cleansers.

One of the newest and fastest growing applications for PET containers is food or beverage packaging, which requires filling at high temperatures. Many foods, especially those with fruit or high fruit content, must be packaged at 180F or higher. This provides pasteurization (sterilization) of the product and container during filling. Ordinary oriented containers, such as packaging bags for soft drinks and soft drinks, tend to shrink and deform when subjected to high temperatures above 160T, which is due to certain stress relaxation. Stress concentrations are created during stretch blow molding to make containers. Techniques have been developed to improve heat resistance during processing, commonly referred to as "heat setting" techniques. Depending on the specific process, there are several processing technology details, highly patented, whereby containers suitable for filling at 190-195F can be produced. Products that require packaging with this characteristic are pure juices. High fruit juice content beverages, tea, certain isotonic and sports drinks, condiments, fruit juice concentrates and certain mineral waters.

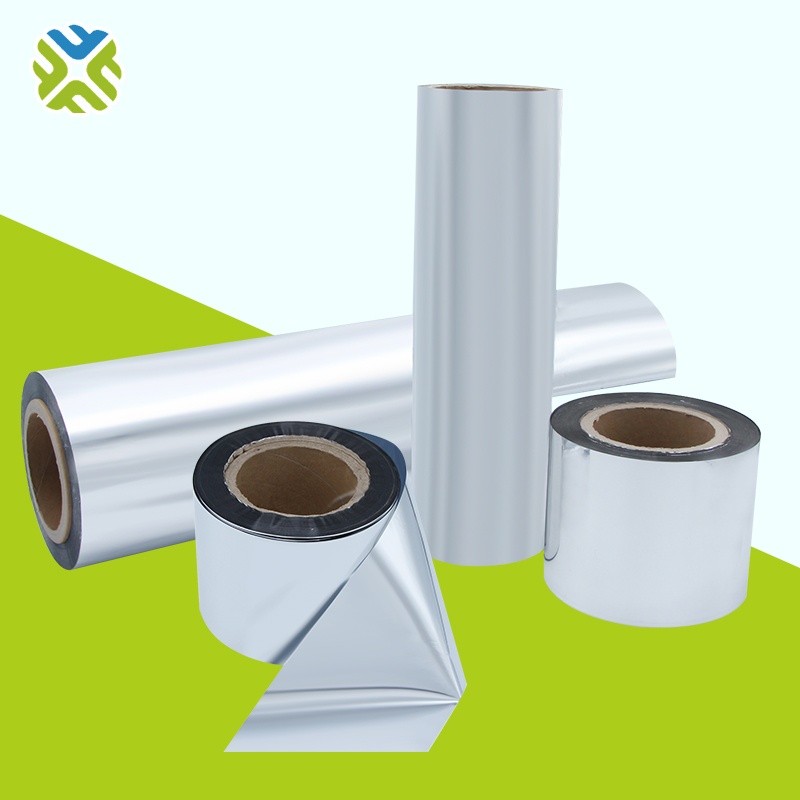

PET films are typically biaxially oriented and are used as X-ray and other photographic films, meat and cheese packaging, magnetic tape, electrical insulation, printing boards and bottle packaging. PET is also used as an industrial tape material. Amorphous, unoriented PET films and sheets began to expand into shaped containers, trays, foamed articles and beverage cups.

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Mobile:+8615169643109

Mobile:+8615169643109

Phone:+8615169643109

Phone:+8615169643109

Whatsapp:+8615169643109

Whatsapp:+8615169643109

Wechat:15169643109

Wechat:15169643109